Overview

The Activated Carbon Pilot Study (ACPS) was performed from September to October 2006 to evaluate the effectiveness of applying and mixing activated carbon in sediments of the lower Grasse River. Activated carbon is widely used in water treatment facilities to remove organic materials from the treated water. Research conducted to evaluate the use of activated carbon in remediating contaminated sediments has shown that PCBs sorb onto the carbon particles and become trapped, making them unavailable to the fish or other river organisms.

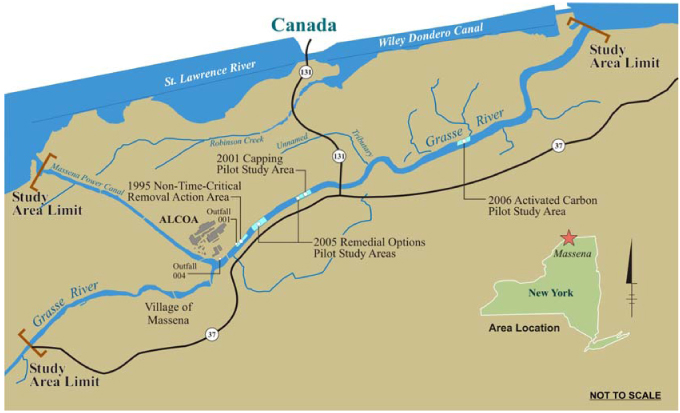

In general, the technology utilized during this pilot study consisted of adding activated carbon to the upper layer of the sediments using specially designed equipment, and monitoring over a multi-year period to determine effectiveness. The ACPS was conducted by Arconic (formerly Alcoa) with oversight from the United States Environmental Protection Agency (EPA; lead), New York State Department of Environmental Conservation (NYSDEC), and the St. Regis Mohawk Tribe (SRMT). The targeted location of the ACPS in relation to previous Arconic pilot studies is shown on the figure below.

Project Details

The technology implemented for this pilot study consists of the addition of activated carbon to the upper layer of the sediment. Laboratory and focused field studies conducted by Stanford University, University of Maryland Baltimore County, and others have demonstrated that mixing activated carbon into surface sediments is effective in reducing the bioavailability of PCBs in sediments to fish and other river-dwelling organisms. The carbon dose is not toxic to humans, fish, or other organisms. The PCBs sorb onto the carbon particles and become trapped, making them unavailable to fish and other organisms. This, in turn, is expected to result in the reduction of PCB levels in both water and fish of the lower Grasse River. Only a thin layer of carbon is necessary to achieve this result. The overall objective of the ACPS is to verify that the bioavailability of PCBs within lower Grasse River sediments can be effectively reduced at the field scale through the addition of activated carbon.

Tiller

Tine Sled

To evaluate the use of activated carbon, Arconic (formerly Alcoa) implemented a pilot demonstration that consisted of:

- Laboratory studies to evaluate the applicability of this technology to Grasse River sediments, and identifying the target application concentration of activated carbon that should be mixed into Grasse River surface sediment (2.5 percent by weight);

- Designing and developing specialty equipment for activated carbon placement including:

- Monitoring conditions in the river before, during, and after dredging and capping activities.

- A "roto-tiller" or tiller – 7 x 12-foot enclosed device that first applied (via spraying) activated carbon onto the sediment surface, followed by mixing of the material into near-surface sediments using the roto-tiller (was used with and without mixing); and

- A "tine sled" – 7 x 10-foot tine sled device that included direct injection of activated carbon into near-surface sediments.

- Field-scale testing of the specialty equipment and placement methods on land to determine if equipment will work as intended;

- A field demonstration of the most promising equipment and placement methods in a 0.5-acre pilot area in the lower Grasse River (described in further detail below); and

- Monitoring activities prior to, during, and after the field demonstration (described in further detail below).

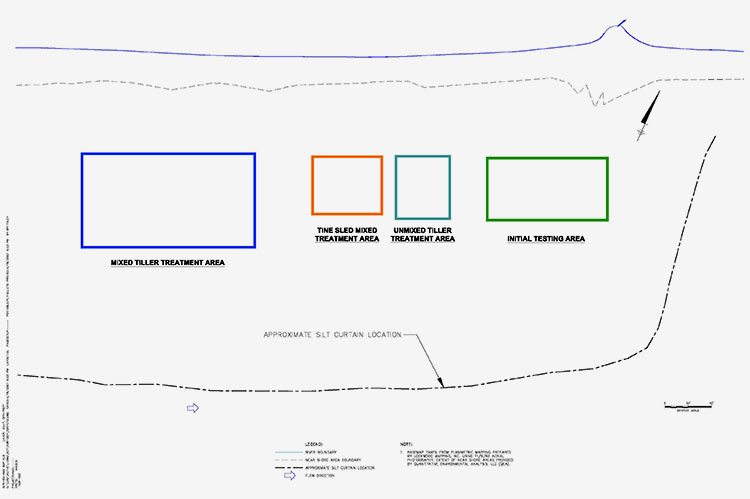

The ACPS field demonstration in the Grasse River was conducted in an approximate 0.5-acre area located in the main channel of the river approximately 2 miles downstream of the Route 131 Bridge. This area was divided into four separate test plots to evaluate the different application techniques and mixing methods. These areas, along with the equipment used to place activated carbon, included:

- Initial Testing Area – tiller with and without mixing and tine sled;

- Mixed Tiller Treatment Area – tiller with mixing;

- Tine Sled Mixed Treatment Area – tine sled; and

- Unmixed Tiller Treatment Area – tiller without mixing.

A silt curtain was used on the downstream and center channel sides of the in-river work area to control any solids and PCBs that may be resuspended during the operation.

As indicated above, baseline, during-construction, and post-construction monitoring was conducted to evaluate potential impacts to the surrounding environment due to activated carbon placement (water column and noise monitoring) and to assess the amount of carbon placed (sediment sampling). Water column and noise monitoring results indicated little to no impacts resulted from implementation of the ACPS. Sediment cores collected immediately following application of activated carbon indicated that an overall average activated carbon increase of 2.5 percent or greater was successfully achieved in each of the treatment areas, although some variability was observed in the measurements. A summary presentation of ACPS activities and monitoring results was given at a community meeting in April 2007.

Photos

Project Site

Project Site

Project Site

Turbidity Curtain

Turbidity Curtain

Tiller Equipment

Tiller Equipment

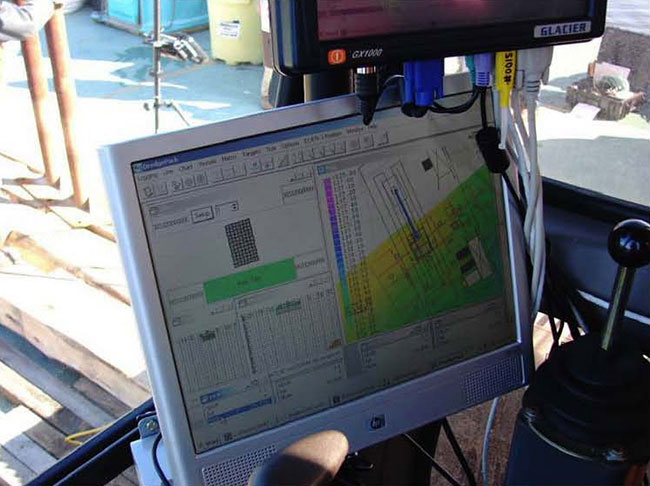

Tiller Position Tracking System

Universal Coupling Attachment

Tiller Equipment

Tiller Equipment

Tine Sled Equipment

Tine Sled Equipment

Tine Sled Equipment

Tine Sled Equipment

Core Sampling

Underwater Video Image During Sediment Core Collection

Back to top